| Separate system server computer | Yes | No | No |

| CIP files for all presses sent to a single hotfolder in the system server computer, typically located in prepress department | Yes | No—Prepress drops files into separate hotfolders, located at each press | No—Prepress drops files into separate hotfolders, located at each press |

| Presetting system can use CIP3, JDF, or TIFF files | Yes | No | No—CIP3 files only |

| Learning feature in presetting system keeps a separate history file for each paper type; maintains a unique presetting curve for every key on the press | Yes | Yes | Yes |

| Preset accuracy reports viewed remotely with a web browser | Yes | No | No |

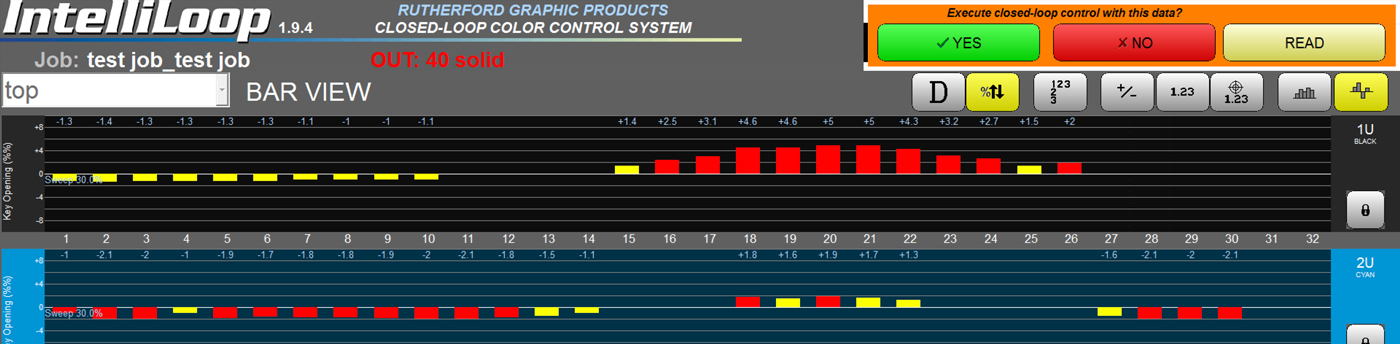

| Rollback feature—Can roll back to the ink-key openings associated with any previous scan | Yes | No—Only the key openings from the most recent scan are shown | No—Only the key openings from the most recent scan are shown |

| Density targets can be assigned to individual or groupings of keys on any color while a job is being run. Resets to defaults when new job is set up | Yes | No—Density target changes apply to all keys across the fountain selected | No—Density target changes apply to all keys across the fountain selected |

| Density-range bar-graph screen—Shows range of densities across each fountain for each scan (Good for system performance review) | Yes | No | No |

| Jobs can be recalled to review system performance | Yes | No | No |

| New: Optional RG-MultiView display on large format monitor. All system apps shown simultaneously and in real time. | Yes | No | No |

| New: Optional RG-Proof—for viewing HD proof at the system touchscreen for verification and content proofing | Yes | No | No |

| New: Optional RG-Dashboard—Displays real-time trending of Density, Delta-E, X-Bar, and Range charts for multiple presses simultaneously on remote large screen; wireless connection | Yes | No | No |

| New: Optional RG-Light Stack—Colors light up to show various statuses: when it's time to scan and pass-fail threshold alerts | Yes | No | No |

| Reads all key openings and sweeps immediately after a scan—manual moves at press console do not affect system key-move accuracy | Automatic or manual command | Automatic or manual command | Manual command only |

| Display actual key openings and sweeps in percentages | Yes | Yes | Yes |

| Operator can preview what the new key openings will be after a scan; can accept or reject such moves | Yes | Yes | Yes |

| Adjustable color correction strengths for makeready and production modes; selection is automatic | Yes | Yes | No |

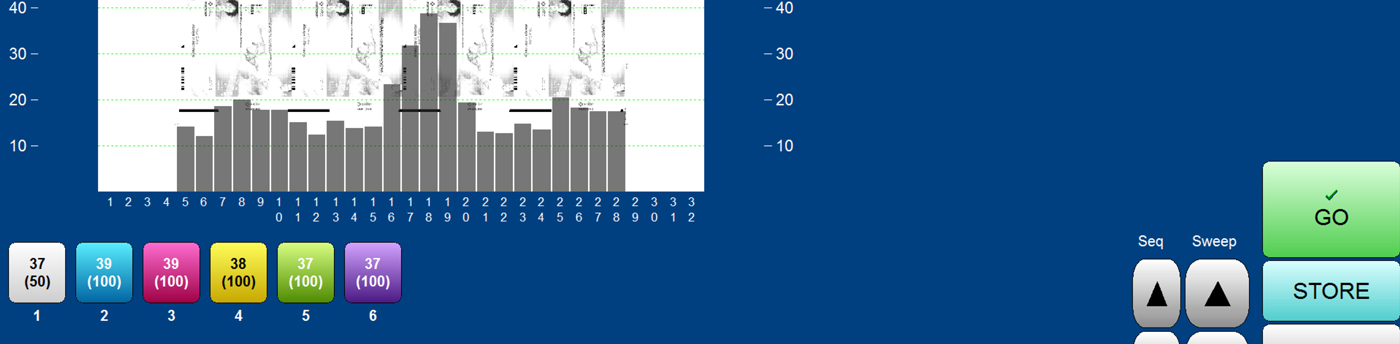

| Preview Presets—Transparent bar graph overlaid on plate image. Sweep values are also shown | Yes | Yes | Yes |